Gundecha Industrial Complex, Kandivali East, Mumbai - 400101

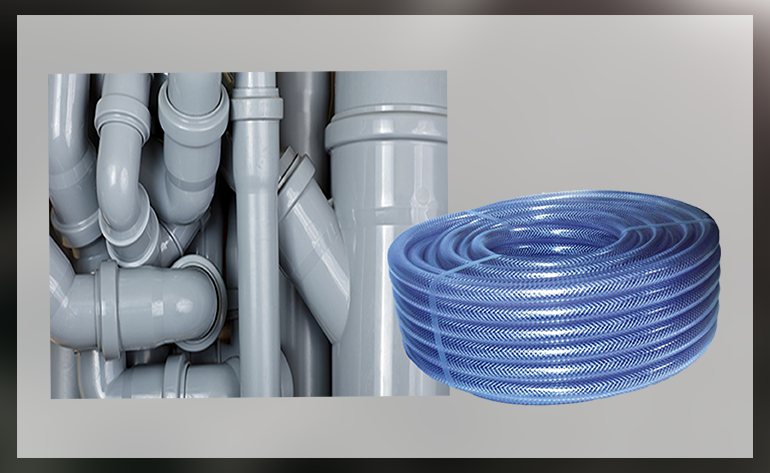

Polyvinyl Chloride (PVC)

Polyvinyl chloride is the world's third-most widely produced synthetic plastic polymer, after polyethylene and polypropylene. PVC comes in two basic forms: rigid (sometimes abbreviated as RPVC) and flexible. The rigid form of PVC is used in construction for pipe and in profile applications such as doors and windows. It is also used in making bottles, non-food packaging, and cards (such as bank or membership cards). It can be made softer and more flexible by the addition of plasticizers, the most widely used being phthalates. In this form, it is also used in plumbing, electrical cable insulation, imitation leather, flooring, signage, phonograph records,[8] inflatable products, and many applications where it replaces rubber.With cotton or linen, it is used to make canvas. Pure polyvinyl chloride is a white, brittle solid. It is insoluble in alcohol but slightly soluble in tetrahydrofuran.

About 80% of production involves suspension polymerization. Emulsion polymerization accounts for about 12%, and bulk polymerization accounts for 8%. Suspension polymerization affords particles with average diameters of 100-180?μm, whereas emulsion polymerization gives much smaller particles of average size around 0.2?μm. VCM and water are introduced into the reactor along with a polymerization initiator and other additives. The contents of the reaction vessel are pressurized and continually mixed to maintain the suspension and ensure a uniform particle size of the PVC resin. The reaction is exothermic and thus requires cooling. As the volume is reduced during the reaction (PVC is denser than VCM), water is continually added to the mixture to maintain the suspension.

The polymerization of VCM is started by compounds called initiators that are mixed into the droplets. These compounds break down to start the radical chain reaction. Typical initiators include dioctanoyl peroxide and dicetyl peroxydicarbonate, both of which have fragile O-O bonds. Some initiators start the reaction rapidly but decay quickly, and other initiators have the opposite effect. A combination of two different initiators is often used to give a uniform rate of polymerization.

After the polymer has grown by about 10 times, the short polymer precipitates inside the droplet of VCM, and polymerization continues with the precipitated, solvent-swollen particles. The weight average molecular weights of commercial polymers range from 100,000 to 200,000, and the number average molecular weights range from 45,000 to 64,000. Once the reaction has run its course, the resulting PVC slurry is degassed and stripped to remove excess VCM, which is recycled.

The polymer is then passed through a centrifuge to remove water. The slurry is further dried in a hot air bed, and the resulting powder is sieved before storage or pelletization. Normally, the resulting PVC has a VCM content of less than 1 part per million. Other production processes, such as micro-suspension polymerization and emulsion polymerization, produce PVC with smaller particle sizes (10?μm vs. 120-150?μm for suspension PVC) with slightly different properties and with somewhat different sets of applications. PVC may be manufactured from either naphtha or ethylene feedstock. PVC is made from petroleum. The production process also uses sodium chloride. Recycled PVC is broken down into small chips, impurities removed, and the product refined to make pure white PVC. It can be recycled roughly seven times and has a lifespan of around 140 years.